DTF Printing (Direct-to-Film) is a game-changing technique in custom apparel decoration, offering unparalleled precision and quality. By digitally printing designs onto specialized heat-transfer films, then applying them to fabrics with heat and pressure, DTF allows for vibrant colors, intricate patterns, and unique personalization. Ideal for fashion lovers and businesses seeking distinctive branding, this method streamlines production, supports various fabric types and ink options, and ensures durable, high-impact decorations for limited-edition items, team uniforms, and personalized gifts. With continuous technological advancements, DTF Printing remains a leading choice for custom apparel decoration due to its efficiency, versatility, and superior design capabilities.

“Revolutionize custom apparel decoration with Direct-to-Film (DTF) heat transfer printing—a game-changer for creating unique, high-quality designs. This method allows for intricate patterns and vibrant colors directly on various fabrics, making it ideal for personalized merchandise. In this comprehensive guide, we’ll explore DTF Printing: from understanding its digital roots to its benefits, detailed process, material choices, and real-world applications. Uncover why this technology is a top pick for businesses and enthusiasts alike.”

- Understanding Direct-to-Film (DTF) Printing: An Overview of the Method

- Benefits of DTF Printing for Custom Apparel Decoration

- The Process: From Design to Final Product Step-by-Step

- Choosing the Right Materials: Substrates, Inks, and Adhesives

- Applications and Use Cases: Where DTF Printing Shines

- Future Prospects and Advancements in DTF Technology

Understanding Direct-to-Film (DTF) Printing: An Overview of the Method

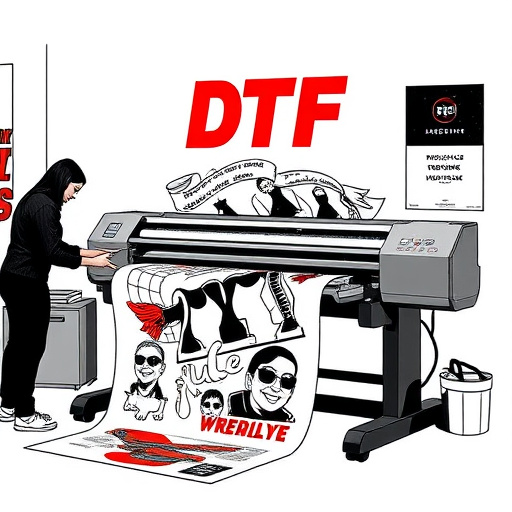

Direct-to-film (DTF) printing is a cutting-edge method revolutionizing custom apparel decoration. Unlike traditional techniques, DTF skips the intermediary steps and transfers designs directly onto fabric using specialized equipment and inks. This innovative approach offers unparalleled precision, vibrant colors, and a seamless finish, making it ideal for creating unique, personalized clothing items.

The process involves several key stages: first, a digital design is created or selected, ensuring it’s optimized for DTF printing. Then, a film—a thin layer of ink—is produced with the design precisely encoded onto it. This film is subsequently applied to the fabric using heat and pressure, enabling the ink to bond directly with the material. The result is an eye-catching, durable decoration that stands out, catering to both fashion enthusiasts and businesses seeking distinctive branding solutions.

Benefits of DTF Printing for Custom Apparel Decoration

Direct-to-film (DTF) printing offers a revolutionary approach to custom apparel decoration, providing numerous benefits that have transformed the way designers and businesses create unique clothing pieces. One of its key advantages is speed and efficiency; DTF Printing allows for quick production times, enabling brands to meet fast-paced market demands with ease. This method eliminates the need for complex setup processes, as designs are directly printed onto heat-transfer films, ready for application onto various fabrics.

Additionally, DTF Printing ensures exceptional quality and vibrancy in colors, making it ideal for intricate and detailed patterns. The technology supports a wide range of ink options, allowing artists to achieve diverse effects, from soft pastel tones to bold, vibrant shades. This versatility caters to different design styles and client preferences, solidifying DTF Printing as a go-to method for custom apparel decoration in today’s fashion industry.

The Process: From Design to Final Product Step-by-Step

The direct-to-film (DTF) heat transfer method for custom apparel decoration is a cutting-edge process that transforms design ideas into unique, personalized garments. It begins with the creation of a digital design, which can be intricate and detailed, incorporating various elements like graphics, text, or patterns. This design is then optimized for DTF printing, ensuring it meets the requirements for heat application.

Once ready, the design is printed directly onto a thin film using specialized equipment. The film acts as a carrier, allowing for precise transfer of the image to the apparel material. After printing, the film is carefully cut around the design, creating individual elements that will be applied to the garments. Next, these elements are precisely positioned on the fabric and heat-pressed using a specialized machine. This process permanently fuses the design onto the apparel, resulting in a high-quality, durable finish. Finally, after cooling, the excess film is removed, leaving only the custom decoration on the garment, ready for wear or sale.

Choosing the Right Materials: Substrates, Inks, and Adhesives

Choosing the right materials is paramount in direct-to-film (DTF) printing for custom apparel decoration. The substrate, or fabric, plays a crucial role in determining the final product’s quality and durability. Cotton, polyester, and their blends are popular choices due to their versatility and ability to absorb ink effectively. For DTF Printing, it’s essential to select fabrics with smooth surfaces to ensure even heat transfer.

Inks and adhesives are equally significant. High-quality inks designed specifically for DTF Printing offer vibrant colors and exceptional fastness on various fabrics. Adhesives should be durable, providing strong bonds that withstand washing and wear. Water-based adhesives are often preferred for their eco-friendliness and ease of use, while also ensuring good print adhesion and flexibility.

Applications and Use Cases: Where DTF Printing Shines

Direct-to-film (DTF) printing has gained immense popularity in the custom apparel decoration industry due to its versatility and exceptional quality. This innovative heat transfer method allows for intricate designs, vibrant colors, and diverse material applications. One of its standout features is the ability to decorate a wide range of fabrics, from cotton tees to polyester jackets, without limitations.

DTF Printing shines in various use cases, including limited-edition merchandise, team uniforms, event souvenirs, and personalized gifts. It enables businesses and individuals to create unique, on-demand products with intricate graphics and textural elements that traditional printing methods might struggle to achieve. The method’s efficiency, coupled with the potential for complex design work, makes DTF Printing a go-to choice for those seeking high-impact, custom apparel decorations.

Future Prospects and Advancements in DTF Technology

The direct-to-film (DTF) heat transfer method for custom apparel decoration is constantly evolving, offering exciting prospects for the future. With advancements in technology, DTF printing is becoming more efficient, versatile, and accessible. The latest innovations focus on improving print quality, expanding the range of materials compatible with DTF, and reducing production times. Higher resolution prints and the ability to incorporate intricate designs are now feasible, opening up new creative possibilities for apparel decorators.

Additionally, the integration of digital technologies like artificial intelligence (AI) and machine learning can streamline the design process, enabling automatic image enhancement and personalized decoration suggestions. As DTF technology continues to refine itself, it promises to become an even more preferred choice for custom apparel decoration, catering to both small-scale artisans and large-volume manufacturers alike.