DTF Transfers (Direct to Fabric printing) offers an affordable way to create custom designs on fabrics, using heat and pressure to apply ink. To ensure high-quality, long-lasting prints, follow these steps: clean and prepare the fabric surface, use high-quality DTF heat transfer paper, allow proper curing time after application, maintain optimal environmental conditions, and regularly clean the application surface. Skimping on these preparation and post-application care steps can lead to peeling or cracking of the transfers.

“Discover the secrets to achieving long-lasting, high-quality DTF (Direct to Film) transfers with this comprehensive guide. DTF printing has revolutionized the industry, but preventing peeling and cracking is essential for maintaining its integrity. This article delves into the common issues afflicting DTF transfers and offers practical solutions. From pre-preparation techniques to post-application care, learn how to navigate the process seamlessly, ensuring your prints remain vibrant and durable.”

- Understanding DTF Transfers and Common Issues

- Pre-Preparation Steps to Prevent Peeling and Cracking

- Post-Application Care Techniques for Longevity

Understanding DTF Transfers and Common Issues

DTF Transfers, or Direct to Fabric, are a popular method for creating custom designs on various materials, from t-shirts to tote bags. This process involves transferring ink directly onto the fabric using heat and pressure, offering a cost-effective way to produce high-quality, personalized items. However, while DTF Transfers boast numerous advantages, they’re not without their challenges. Common issues include peeling or cracking of the transferred design, which can be attributed to factors like improper printing techniques, inadequate heat application, or subpar materials. Understanding these potential problems is the first step towards ensuring pristine DTF prints.

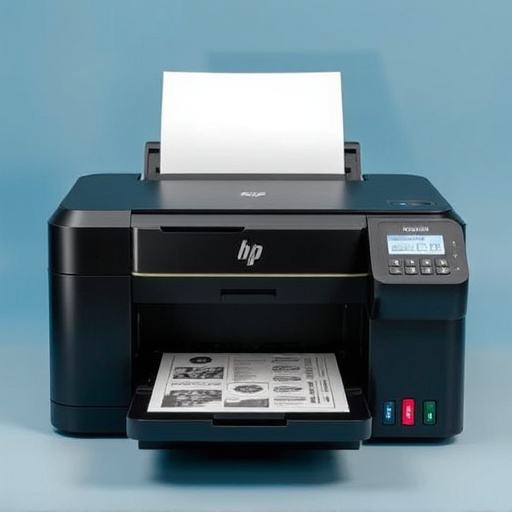

The key to avoiding peeling or cracking lies in meticulous preparation and execution. Using a best dtf printer that’s calibrated accurately for temperature and pressure is crucial. Additionally, selecting suitable ink types compatible with your printer and fabric choice can significantly impact the longevity of the transfers. Employing proper cleaning and maintenance routines for your printing equipment also plays a vital role in maintaining consistency and quality across batches of custom DTF transfers.

Pre-Preparation Steps to Prevent Peeling and Cracking

Before applying DTF (Direct to Fabric) transfers, taking a few preparatory steps can significantly reduce the likelihood of peeling or cracking. Start by cleaning and preparing the fabric surface thoroughly; ensure it’s free from dust, oil, or any previous residue. This initial step is crucial as contaminants can lead to poor adhesion and eventual peeling.

Additionally, selecting the appropriate DTF printing for hoodies or other garments is essential. Using high-quality DTF heat transfer paper designed for optimal adhesion and durability can make a world of difference. Avoid using inferior papers that might not bond well with fabrics, leading to cold peel dtf transfers and subsequent cracking. Proper pre-preparation sets the stage for long-lasting, vibrant prints on your fabric items.

Post-Application Care Techniques for Longevity

After applying DTF transfers, proper post-application care is essential to maintain their longevity and prevent peeling or cracking. One crucial technique is to allow the transfer to cure completely before handling it. This process involves leaving the transferred design untouched for a specific duration, typically recommended by the manufacturer. During this time, the adhesive sets, ensuring a strong bond with the substrate.

Additionally, maintaining optimal environmental conditions can significantly impact the durability of DTF prints. Avoiding extreme temperatures and direct sunlight helps prevent premature aging or degradation of the transfer. Regular cleaning of the surface where the DTF transfers are applied is also vital to remove any dirt or grease that could compromise their adhesion. Using mild detergent and a soft cloth ensures the surface remains clean without damaging the delicate design.

DTF Transfers can be a game-changer for creating durable, vibrant art, but peeling and cracking are common issues. By understanding these problems and implementing pre-preparation steps like surface cleanliness and proper adhesive selection, you significantly reduce the risk. Post-application care, including avoiding moisture and excessive heat, ensures longevity of your DTF creations. Following these simple tips can help you achieve professional results with minimal hassle, keeping your DTF Transfers looking sharp for years to come.