DTF Transfers revolutionize fabric design with direct-to-fabric printing, offering unparalleled versatility and quality for custom clothing and promotional items. This process utilizes specialized inks and equipment to produce intricate, vibrant designs with exceptional detail, requiring meticulous preparation of design files and fabrics. DTF transfers are also powerful tools for exchanging digital data across systems, ideal for rapid delivery of large datasets like e-commerce product catalogs. They transform the printing landscape with cutting-edge capabilities, enabling high-quality prints directly on film stock and integrating seamlessly into production lines.

In today’s digital landscape, efficient and secure handling of DTF (Data Transfer Format) transfers is paramount. DTF transfers, known for their compactness and speed, are indispensable in various sectors, from finance to healthcare. However, improper storage or handling can lead to data breaches, corruption, or loss. This article guides you through the intricacies of DTF transfers, offering best practices for secure storage, effective handling techniques, and strategies to mitigate risks, ensuring your data remains intact and accessible only to authorized personnel.

- Understanding DTF Transfers and Their Unique Requirements

- – Definition of DTF (Data Transfer Format) transfers and their common use cases.

- – Key characteristics and benefits of DTF transfers.

Understanding DTF Transfers and Their Unique Requirements

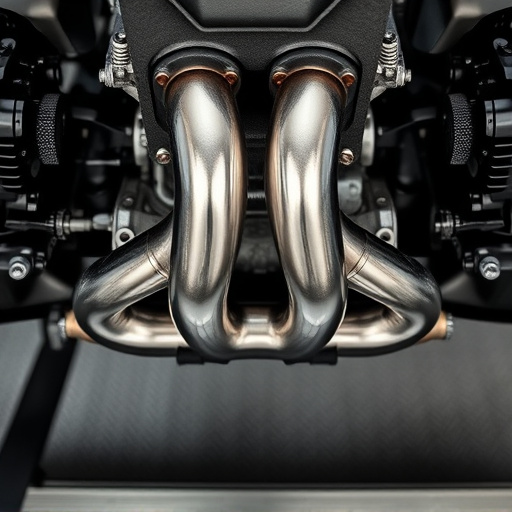

DTF Transfers, or Direct to Fabric, are a cutting-edge method for applying designs to various materials, particularly textiles. This innovative process involves printing directly onto fabric using specialized equipment and inks, allowing for intricate and vibrant designs. Unlike traditional transfer methods, DTF Transfers offer unmatched versatility and quality, making them a popular choice for custom clothing, promotional products, and more.

Understanding the unique requirements of DTF Transfers is essential for achieving optimal results. The process demands precise preparation of both the design file and the fabric to ensure proper adhesion and long-lasting durability. Careful consideration should be given to factors like ink type, print resolution, and heat application during the dtf application instructions. Additionally, choosing the right dtf printed shirts or materials for your project is crucial to accommodate the specific needs of this technology, ensuring a final product that stands out with its crisp details and vibrant colors.

– Definition of DTF (Data Transfer Format) transfers and their common use cases.

Data Transfer Format (DTF) transfers are a common method for exchanging digital data between different systems or applications. DTF files are designed to facilitate quick and efficient transfer of information, making them ideal for various use cases across industries. These transfers are particularly useful in scenarios where fast delivery of large datasets is required, such as in e-commerce platforms where product catalogs need to be updated regularly.

DTF transfers are also known for their cost-effectiveness, especially when compared to traditional methods like manual data entry or complex integration processes. They are ready-to-press, meaning the data is structured and prepared for immediate use upon receipt, further streamlining workflows and reducing potential errors. This efficiency makes DTF a preferred choice for organizations seeking to optimize data handling operations without compromising on quality or speed.

– Key characteristics and benefits of DTF transfers.

DTF (Direct to Film) transfers offer a cutting-edge solution for creating high-quality prints and graphics directly onto film stock. This innovative technology has revolutionized the printing industry, providing several key benefits that traditional methods can’t match. With DTF transfers, businesses and artists can achieve vibrant, detailed results with a wide range of material options, from clothing to signage.

One significant advantage is their versatility; DTF transfers are ready to press, meaning they can be easily integrated into various production lines. Custom DTF transfers allow for precise color reproduction, ensuring every design element is accurately represented. This technology is particularly prized for its ability to handle intricate patterns and fine details, making it suitable for both mass production runs and one-off, specialized projects.

DTF Transfers, with their efficient data handling capabilities, are transforming how information is exchanged in various industries. By understanding their unique requirements and adhering to proper storage and handling practices, organizations can maximize the benefits of this format. Implementing best practices ensures data integrity, compatibility across systems, and streamlined workflows, ultimately revolutionizing data management processes.