DTF Transfers (Direct-to-Fabric) revolutionize clothing customization with precise, vibrant prints on fabric via heat and pressure. Key steps include design preparation (high resolution for size), material selection (ink absorption rates), and application. Gather tools like high-quality transfers, a heat press machine, and protective fabrics. Ensure proper surface cleaning and heat press settings for optimal adhesion. Precise positioning and UV curing create long-lasting images. Techniques like heat pressing and gang sheet builders enhance application for best results.

“Unlock the art of transforming surfaces with DTF (Direct to Film) transfers—a versatile and innovative technique gaining popularity. This step-by-step guide is designed to empower beginners and seasoned crafters alike. From understanding the fundamentals of DTF transfers and gathering essential tools, to mastering application techniques, each section offers valuable insights. Discover how to create stunning designs on various materials, from fabrics to wood, with ease and precision. Elevate your projects with this powerful DIY method.”

- Understanding DTF Transfers: What You Need to Know

- Preparing Your Surface and Materials

- Applying the Transfer: Techniques and Tips

Understanding DTF Transfers: What You Need to Know

DTF Transfers, or Direct-to-Fabric transfers, have revolutionized the way we personalize and decorate clothing and textiles. This cutting-edge technology allows for precise application of designs directly onto fabric surfaces, offering a versatile and cost-effective method for creating custom apparel and accessories. By using heat and pressure, DTF transfers bond durable inks to various fabrics, resulting in vibrant print quality that withstands frequent washing and wear.

Understanding the mechanics behind DTF Transfers is key to achieving optimal results. The process involves three main components: design preparation, material selection, and application. When preparing your design, ensure it’s high-resolution and optimized for the specific dtf transfer by size you intend to use. For instance, larger transfers may require higher resolution to maintain detail. Similarly, selecting the right fabric is crucial; different materials, from cotton t-shirts to polyester sweatshirts, absorb ink differently, impacting both dtf print quality and overall product durability.

Preparing Your Surface and Materials

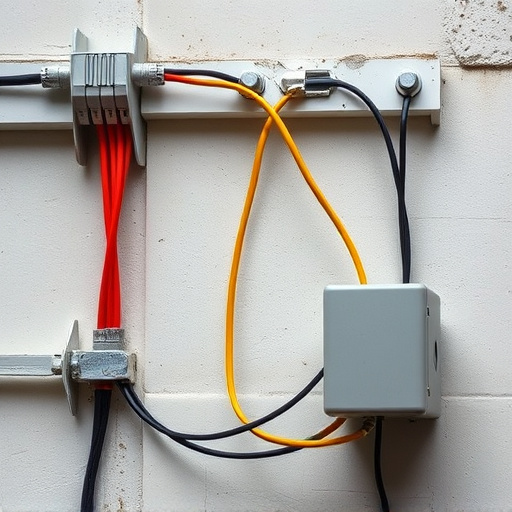

Before you begin applying DTF (Direct-to-Fabric) transfers, ensuring your work area is prepared and your materials are ready is essential for achieving professional results. Start by gathering all necessary tools and supplies: this includes high-quality DTF transfers designed for your desired fabric type, a heat press machine, and appropriate press fabrics or paper to protect the transfer during application. Clean and prepare your surface; depending on the material, you might need to wash and dry it first to ensure optimal adhesion. For DTF printed shirts or other textiles, consider using a suitable primer to enhance the bonding process.

Follow specific dtf application instructions for each type of fabric to guarantee the best transfer quality. Ensure your heat press is set at the correct temperature and pressure settings recommended by the manufacturer. Have all your materials within reach—including any additional tools like spray bottles for moisture control or timing devices to monitor press duration—to streamline the process and make the most of your creative time. With these preparations in place, you’re ready to embark on creating stunning designs with DTF transfers.

Applying the Transfer: Techniques and Tips

Applying DTF Transfers requires a precise touch and an understanding of the unique properties of Direct to Film (DTF) technology. The first step involves carefully positioning the transfer sheet onto the target surface, ensuring no air bubbles are trapped between the film and the substrate. This process demands patience and careful alignment, especially when working with intricate designs or larger areas.

Once positioned, the key to successful application lies in the curing process. DTF transfers utilize UV light to set the ink, so a suitable LED lamp is essential. Maintain a consistent distance between the lamp and the transfer sheet for even curing. After the curing process is complete, gently peel away the backing film, revealing the vibrant, long-lasting image. Experimenting with different techniques and materials, like using a gentle heat press or exploring various DTF gang sheet builders, can further refine the application method, ensuring optimal results for your specific project requirements.

DTF Transfers offer a creative and efficient way to transform surfaces with intricate designs. By following these steps, from understanding the process to applying the transfer accurately, you can achieve professional results. With the right preparation and techniques, DTF Transfers are accessible to all, enabling you to customize and elevate various materials. Whether for personal projects or business ventures, this guide equips you with the knowledge to explore the versatility of DTF technology.