DTF Transfers revolutionize custom printing with precise, intricate design application directly onto fabrics, offering unparalleled versatility and quality from cotton to polyester. Advancements in technology make DTF printers more accessible, fostering creativity for high-impact personalized garments. This method streamlines production using heat presses, reducing time and costs compared to traditional methods. Future innovations focus on enhancing efficiency, quality, and sustainability, making DTF transfers a game-changer in personalized merchandise.

The future of custom printing is here with Direct-to-Transfer (DTF) technology, revolutionizing the way we personalize products. This innovative process allows for precise, high-quality designs on a variety of surfaces, fueling the growth of custom printing in today’s market. From clothing to accessories and beyond, DTF transfers offer unmatched versatility and efficiency. Explore the transformative potential of DTF technology, its growing benefits, and the exciting future trends shaping this dynamic industry.

- Understanding DTF Transfers: A Modern Revolution

- The Growth and Benefits of Custom Printing

- Future Trends: Innovation in DTF Technology

Understanding DTF Transfers: A Modern Revolution

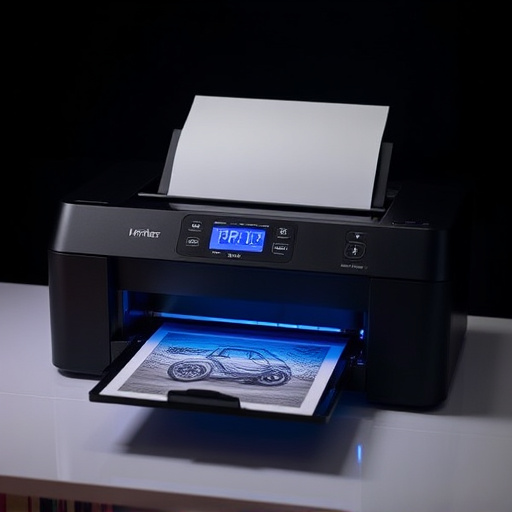

DTF Transfers are paving the way for a revolution in the custom printing industry. This modern technique allows for intricate and detailed designs to be applied directly onto fabrics, particularly garments, with remarkable precision and efficiency. By utilizing a direct-to-fabric (DTF) printer, artisans and entrepreneurs can now create custom sheets that serve as templates for heat pressing these designs.

The appeal of DTF Transfers lies in their versatility and quality. They enable the production of vibrant, long-lasting prints on a variety of materials, from cotton tees to polyester jackets. With advancements in technology, best DTF printers are becoming more accessible and affordable, democratizing access to this once specialized process. This has opened up new opportunities for businesses and individuals to express their creativity through personalized, high-impact garments.

The Growth and Benefits of Custom Printing

The custom printing industry has witnessed a significant surge in demand, driven by the ever-evolving trends in personal expression and product customization. At the forefront of this revolution is DTF (Direct to Fabric) transfers, a technology that offers unparalleled versatility and quality. With DTF Transfers, businesses can now efficiently produce customized designs on various fabrics, from t-shirts to mugs and even phone cases. This method has democratized printing, enabling individuals and small enterprises to create unique, personalized items at scale.

One of the key benefits of DTF Transfers is its ability to streamline production processes. Unlike traditional printing methods that might require specialized equipment and lengthy setup times, DTF uses heat presses to apply designs directly to fabrics, reducing production time and costs. Additionally, it allows for a wide range of design possibilities, including intricate details and vibrant colors, ensuring that custom-printed products meet the high standards expected by today’s consumers. This technology is particularly advantageous for bulk DTF heat transfer paper orders, making it ideal for bulk DFT shirt production.

Future Trends: Innovation in DTF Technology

The future of custom printing holds immense potential with Direct-to-Film (DTF) technology continuing to evolve and revolutionize the industry. Innovations in DTF transfers aim to enhance efficiency, quality, and sustainability, making personalized merchandise more accessible and appealing. One prominent trend is the integration of advanced materials and ink formulations, enabling printers to achieve vibrant colors, crisp details, and a wider range of applications. This advancement promises to take custom dtf transfers to new heights, catering to diverse markets from fashion to sportswear.

Additionally, automation and digital connectivity are set to play a significant role in shaping the future of DTF printing. Automated systems streamline production processes, reducing human error and increasing output speeds. Cloud-based platforms could also enable remote access to designs and orders, fostering seamless collaboration between designers, printers, and customers. These trends collectively point towards a more efficient, interconnected, and dynamic landscape for custom printing with DTF transfers, further solidifying its position as a game-changer in the world of personalized merchandise.

DTF transfers are poised to transform the custom printing industry, offering unparalleled versatility and quality. As technology continues to advance, we can expect even more innovative applications, faster production times, and enhanced durability. The future of custom printing with DTF transfers looks bright, promising endless possibilities for businesses and individuals alike to express their creativity and unique designs on a variety of products.